FAST AND RELIABLE INGREDIENTS MIXING

Rapid and reliable production thanks to high shear and energy dissipation rates

A completely sealed system (compliant with EHEDG and 3A) ensures food safety

Vacuum system consumes 50% less water and 70% less energy than competing models, keeping operational costs in check

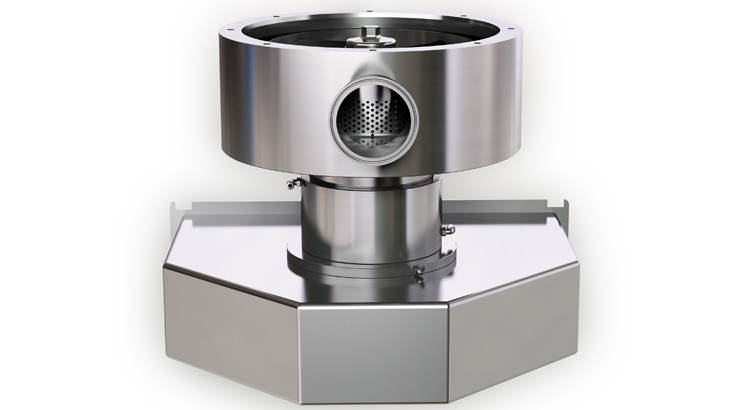

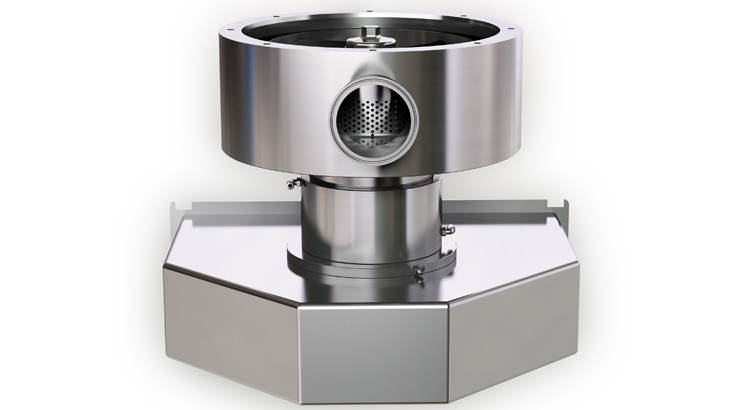

Tetra Pak® High Shear Mixer

Recirculation mixer for the emulsification and hydration of powders and other ingredients, and the standardization of milk.

CAPACITY

5,000 l/h – 40,000 l/h

APPLICATIONS

Formulated dairy products

Note: this product has been renamed, old name: Tetra Almix

FEATURES

Automated, closed system

Enhances food safety

There is no risk of contamination entering the system since it is completely sealed to maintain product hygiene. In fact, the whole mixer is designed for sanitary execution and can be configured to meet the regulations for both EHEDG and 3A.

Shelf life of the end product is also lengthened by deaeration, since it makes the environment inhospitable for microorganisms.

Vacuum system

Enables efficient mixing

The vacuum system allows for automatic dosing of powder ingredients in a controlled and reliable manner. It draws ingredients into the mixer, eliminating the need for an operator to do this heavy work. The product is deaerated (i.e. the air is removed from it) enabling higher uptime in the rest of your downstream line. When there is air in the product, this causes burn-on in the downstream equipment, implying a need for more frequent cleaning.

High shear head

Enables efficient, fast and repeatable mixing

This is the heart of the high shear mixer unit. Shear and energy dissipation rates are significantly higher here than in conventional mixing vessels. The mixer is therefore suitable for solid to liquid dispersion, dissolving and emulsification, as well as liquid to liquid homogenization and emulsification. The mixing process is so intense it can even dissolve notoriously difficult ingredients like pectin in seconds.

Frequency converter

Economical use of utilities

Once 500 mb has been reached in the tank, a frequency converter fitted to the mixer's vacuum system, regulates the motor to the necessary level. The control system communicates the amount of vacuum (under-pressure) needed at any given step in the process. Whenever the motor slows down, it heats the water (used to seal the vacuum pump) less. The water therefore remains at the correct working temperature for a longer period. This reduces overall water consumption by up to 50% and energy consumption by up to 70%.

Powder valve

Enables trouble-free powder handling

The powder valve is unique to Tetra Pak's high shear mixers. It closes immediately if there is a loss of vacuum for any reason. This eliminates the risk of back flow into the powder system, and prevents blockages, which would stop production.

Automated level control

Enables smooth, uninterrupted production

The level control works in combination with the product inlet/outlet to keep the right amount of fluid circulating in the system. If the level gets too high or too low, the load cells and frequency controlled outlet pump return it to the desired level. The amount of powder in the mix also fluctuates during production (be it e.g. sugar, lactose, stabilizers). Regardless of how much powder is entering the mixer, this system maintains steady production.