Food & Beverage: Multi-Circuit

Food and Beverage Clean-In-Place Multi-Circuit Systems

A Space-Saving CIP System to Clean Multiple Process Lines or Tanks Simultaneously

Many processors have large production capacity with multiple process lines and vessels, which require a lot of time to clean. And every processor wants to minimize the amount of time spent cleaning and increase valuable production time.

What can a processor do to decrease cleaning time and increase production time? Additional CIP systems can be installed at a facility, but that requires a significant amount of floor space and a large financial investment. A more cost- and space-saving option is a Sani-Matic Multi-Circuit CIP System.

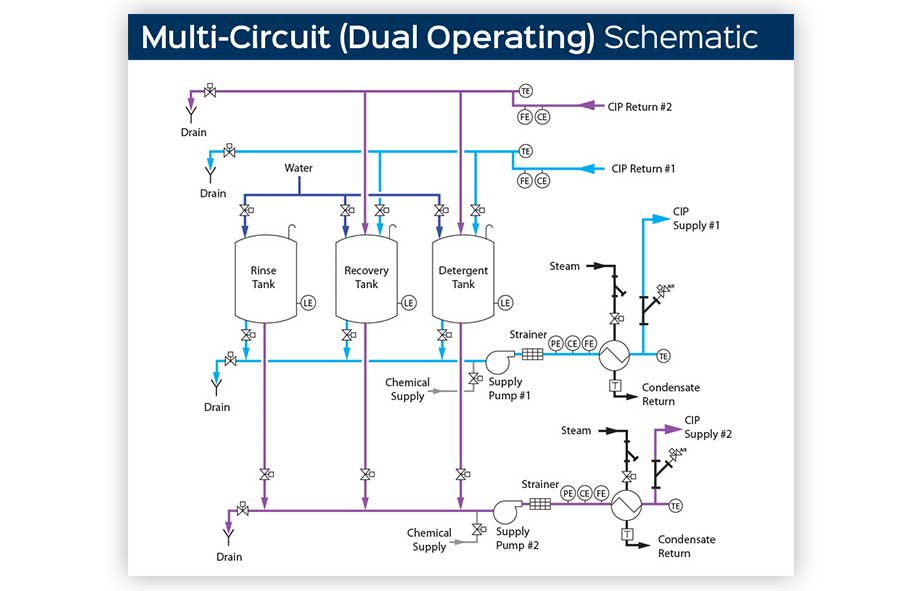

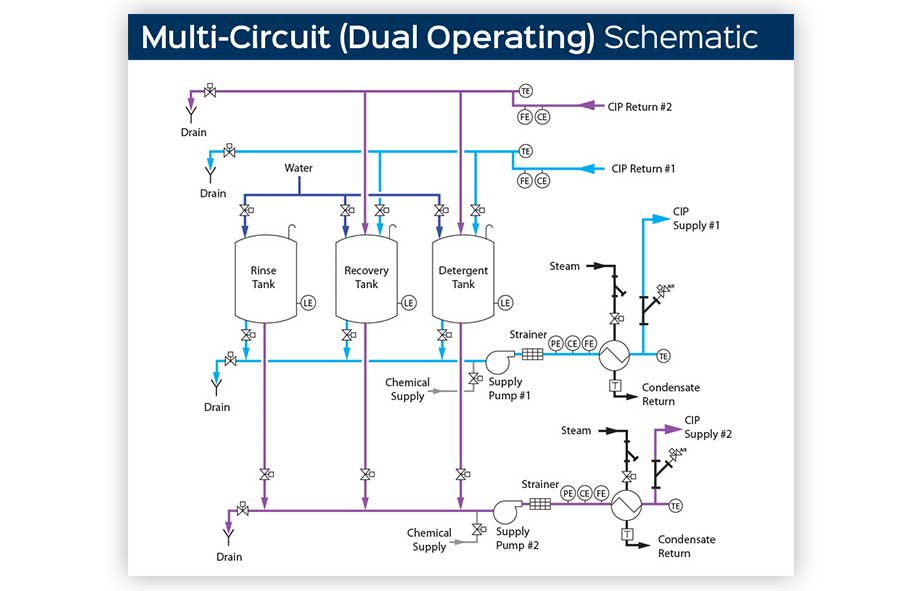

A Sani-Matic Multi-Circuit CIP System is one system with multiple circuits and shared tanks. This design allows the system to clean multiple processes, the same as multiple single circuit CIP systems would, while providing significant space and cost savings—and cutting cleaning time by 50% for dual circuits and 25% for quad circuits.

Do you want to increase the production time for your high-capacity process? A Sani-Matic Multi-Circuit CIP System may provide the Cleaning Confidence, and bottom line boost, you are looking for.

BENEFITS

Increased productivity

Serves multiple circuits simultaneously

Savings

Substantial cost and space-saving advantages over multiple single circuit units

Reduced wash and rinse cycle times

Flexibility

Centralized controls