FLASH PASTEURIZATION FPS

Principle & Description

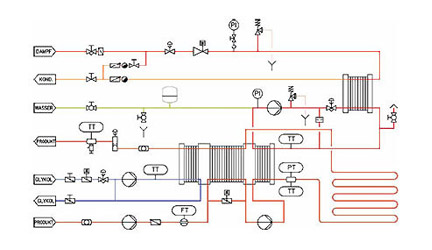

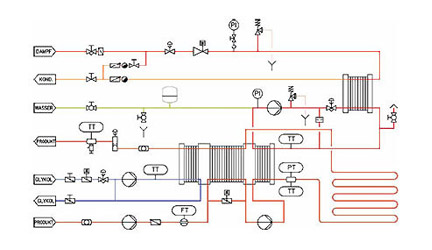

The Flash Pasteurization System (FPS) pasteurizes beer, beer mix drinks and carbonated beverages. The product is gently heated up to the pasteurization temperature regeneratively and then via a hot water circuit. Then it is cooled down regeneratively and further cooled with glycol or ice water after passing the holding pipe.

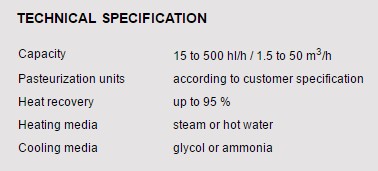

The process is well established in the brewing and beverage industry for providing long product stability and high quality. The system is characterized by gentle product treatment, exact control of pasteurization units, high operational reliability and high heat recuperation up to 95%

Very gentle pasteurization of beer and carbonated beverages

Exact control of programmed pasteurization units (PU)

High heat recuperation up to 95%

Broad capacity range of 40 – 100 % of nominal capacity

Hygienic design, full CIP capability

Easy operation, low maintenance effort, long service life

Fully automatic operation with standard PLC and touch panel

Optional integration in process control system and remote maintenance

Individually dimensioned and designed for each specific application

Equipment and components according to customer specification

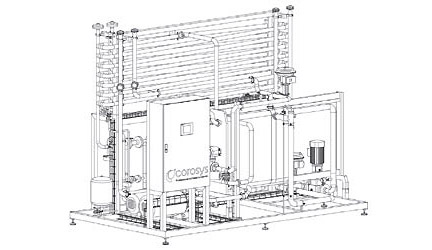

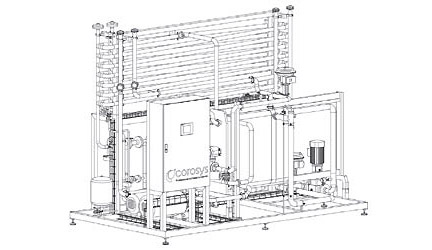

Compact tubular-frame system (skid mounted)

TECHNICAL DESCRIPTION

weiterlesen The product is gently heated up to the pasteurization temperature regeneratively and then via a hot water circuit. Temperature and flow are controlled to keep the pasteurization units within very narrow limits. Then the product is cooled down regeneratively and further cooled with glycol or ice water after passing the holding pipe.

The two centrifugal pumps in serial arrangement maintain the pressure significantly above saturation pressure at the pasteurization temperature to keep all CO2 dissolved. Due to the second booster pump, the pressure in the pasteurized product is always higher than the pressure in the non-pasteurized product in order to avoid contamination due to leakage. If the filler stops, the product is ejected with deaerated water, controlled by volume or conductivity. If filling runs up again, the deaerated water is ejected again with the product.

The unit can be controlled by a local PLC with a touch panel or by a process control system.

Designed for high hygienic standards, all common cleaning agents in the brewing and beverage industry can be used for CIP cleaning.