Principle & Description

The corosys ethanol metering skid continuously measures both the mass flow and the ethanol concentration with extremely high precision. The system calculates and counts the produced volume of alcohol water mixture (AWM) and pure ethanol at a reference temperature of 20°C, for registration by the customs office. Additionally, the average alcohol concentration is calculated and displayed.

The ethanol metering skid is used in ethanol fuel production, distilleries or dealcoholisation systems for recording the ethanol production volume for customs registration. A more simple system can be used to measure and control alcohol concentration and flow in any production process.

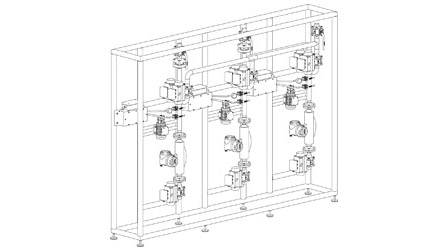

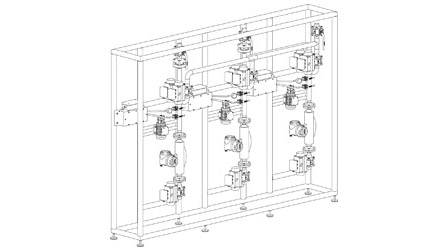

The ethanol metering skid can be installed with a second redundant metering track if operational availability is of importance. A third metering track can be added for feeding non spec ethanol back into the production plant.

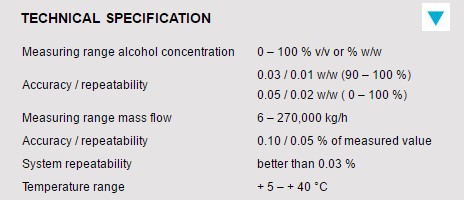

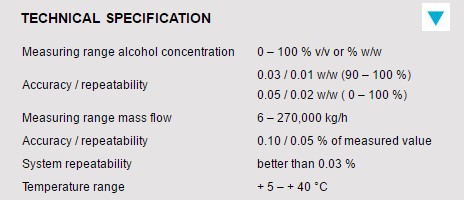

Extremely accurate metering of mass flow and ethanol concentration

Calculation of produced ethanol volume at a reference temperature of 20°C

Individually dimensioned and designed for each specific application

System prepared for lead sealing by authorities

Easy operation, low maintenance effort, long service life

Fully automatic operation

Optional integration in process control system

Highest availability due to redundancy

TECHNICAL DESCRIPTION

weiterlesen A Coriolis mass flowmeter measures the mass flow of ethanol in the main stream. The alcohol concentration is measured in a bypass by an extremely precise density meter of Anton Paar, Graz, Austria. The signals of both instruments are evaluated by a flow computer. The volume of the alcohol / water mixture and the volume of pure ethanol at a reference temperature of 20°C is calculated, counted and stored.

The calibration of the metering skid can be carried out with a special tank standing on calibrated load cells. Instruments, valves and pumps are built into a stainless steel frame. The flow computer, a protocol printer and mechanical counters are installed in a switch cabinet outside the explosion proof area. Metering skid and switch cabinet are prepared for lead sealing.