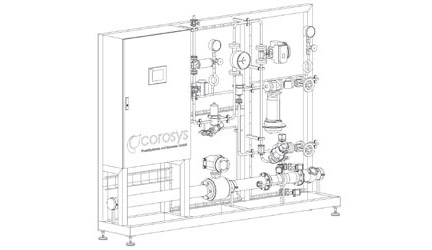

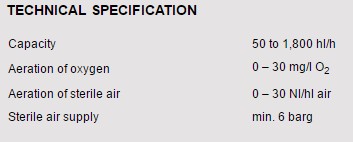

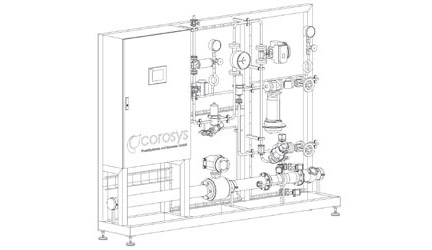

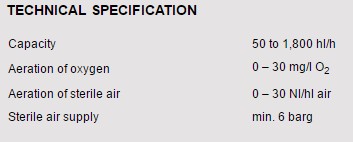

CONTINUOUS WORT AERATION CWA

Principle & Description

The Continuous Wort Aeration (CWA) continuously and highly accurately injects sterile air or oxygen into beer wort. The corosys GDI gas injector splits the air into extremely small bubbles, maximizes the oxygen saturation and in this way provides reliable and reproducible fermentation.

The continuous process is employed in the brewing process between wort cooler and fermenter while transferring the wort. The system is characterized by highly accurate and reliable flow measurement technology and precise control algorithms. The corosys GDI gas injector ensures quick and complete saturation of the air.

Continuous, accurate aeration of wort with sterile air or oxygen

Highly efficient gas injector, low pressure drop, maximum dissolution

Optional in-line oxygen analyzer

Hygienic design, full CIP capability

Easy operation, low maintenance effort, long service life

Fully automatic operation with standard PLC and touch panel

Optional integration in process control system and remote maintenance

Individually dimensioned and designed for each specific application

Equipment and components according to customer specification

Compact tubular-frame system (skid mounted)

TECHNICAL DESCRIPTION

weiterlesen Sterile air or oxygen is injected into the wort via the GDI gas injector developed by corosys. The gas injector splits the air / oxygen into very small bubbles and provides quick and complete saturation. The wort pipe between wort cooler and fermenter functions as a holding pipe.

The volume flow of wort and the mass flow of air / oxygen are measured. The mass flow of air / oxygen is adjusted in a specified relationship to the wort flow by a control algorithm.

The unit can be controlled by a local PLC with a touch panel or by a process control system.

Designed for high hygienic standards, all common cleaning agents in the brewing and beverage industry can be used for CIP cleaning. The injector is cleaned with every CIP of the wort pipe via a bypass. The air / oxygen piping is sterilized with steam.