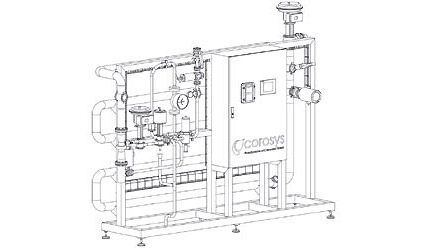

CARBONATION SYSTEM CCS

Principle & Description

The Carbonation System (CCS) continuously and highly accurately controls the CO2 content of beer, beer mix drinks, soft drinks and mineral water by precisely regulated dosing of CO2. The process is well established in the brewing and soft drink industry for the production of carbonated beverages. It can be installed between beer filtration and BBT as well as directly before the filler. A blending system or a premixer can be combined with the unit.

The system is characterized by highly accurate and reliable analyzers and precise control algorithms. The corosys CO2 gas injector splits the CO2 into very small bubbles and ensures dissolving.

Continuous, highly accurate adjustment of the CO2 content

Highly efficient CO2 injector, low pressure drop, complete dissolving of CO2

Optional in-line oxygen analyzer

Hygienic design, full CIP capability

Easy operation, low maintenance effort, long service life

Fully automatic operation with standard PLC and touch panel

Optional integration in process control system and remote maintenance

Individually dimensioned and designed for each specific application

Equipment and components according to customer specification

Compact tubular-frame system (skid mounted)

TECHNICAL DESCRIPTION

weiterlesen CO2 is injected into the beer via the GDI gas injector developed by corosys. The gas injector splits the CO2 into very small bubbles and ensures that the CO2 completely dissolves in a very short time. The system works without using a static mixer. The homogeneous dispersion and the absence of gas bubbles can be monitored by a sight glass situated at the outlet of the dissolving path.

The CO2-content is continuously measured in-line at the outlet of the unit. The product specific set point is compared with the process value and the CO2 flow is adjusted accordingly by a control algorithm. The control valve, which is located at the end of the dissolving path, keeps the pressure in the system constant, even if the flow is unsteady.

The unit can be controlled by a local PLC with a touch panel or by a process control system.

Designed for high hygienic standards, all common cleaning agents in the brewing and beverage industry can be used for CIP cleaning.