ADDITIVE DOSING SYSTEM ADS

Principle & Description

The Additive Dosing System (ADS) continuously and accurately doses malt extract, hops products, flavors, enzymes and other additives to beer, beer wort and other beverages. The additives can be dosed from containers, canisters or a dosing vessel with optional heating jacket.

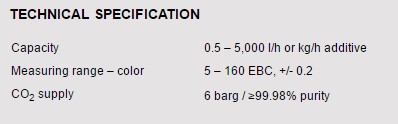

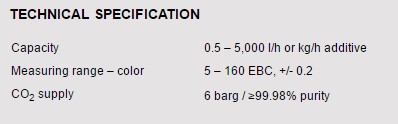

Additive dosing systems are commonly used in the brewing and beverage industry, but also in the chemical-pharmaceutical industry. Making use of this technology provides the greatest possible production flexibility. The systems are characterized by highly accurate metering systems for volume and mass flow and precise control algorithms. Optionally the dosing can be controlled by in-line color sensors or other suitable in-line analyzers.

Continuous dosing of additives, such as malt extract, hops products, and flavours

Precise dosing in relation to the amount of product, with set point in g/hl or ml/hl

Optional in-line color measurement and control in EBC units

Automatic ejection of product and rinsing of system after each production batch

Hygienic design, full CIP capability

Easy operation, low maintenance effort, long service life

Fully automatic operation with standard PLC and touch panel

Optional integration in process control system and remote maintenance

Individually dimensioned and designed for each specific application

Equipment and components according to customer specification

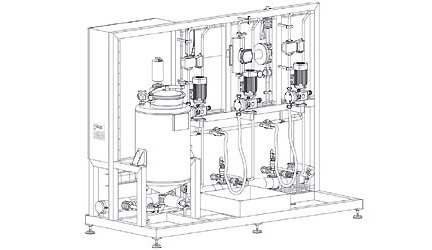

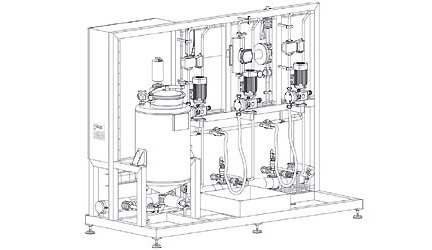

Compact tubular-frame system (skid mounted)

TECHNICAL DESCRIPTION

weiterlesen The flow of product is measured by an electromagnetic flow meter at the inlet of the system. The system doses the additives according to product flow and in a fixed rate given by the recipe for malt extract, hops products, flavours or enzymes. The flow of additives is controlled by frequency controlled metering pumps or by control valves.

The dosing takes place directly in-line and via a hygienic valve combination. CO2 can also be applied to the container or the dosing vessel to avoid contamination with oxygen. At the end of production, the complete dosing system can be rinsed with water and cleaned via a CIP station.

The unit can be controlled by a local PLC with a touch panel or by a process control system.

Designed for high hygienic standards, all common cleaning agents in the beverage and chemical-pharmaceutical industry can be used for CIP cleaning.