CLOSED LOOP ROTARY DRYER

Turnkey Projects Installations

Impressive advantages

Reduces operation and transport costs drastically

Produces Class A Biosolids in a safe and enclosed environment

Operates with minimal supervision due to its high level of automation

Provides stable and reliable operation adaptable to frequent product variations

Generates no noise or odor disturbances in the neighborhood

Operates on various alternative heat sources, including biogas, biomass and thermal fluids

Requires minimal space

Closed Loop Rotaty Dryer

Reliable equipment – Useful and ecological end product

Dries municipal and industrial sludge and produces pellets reusable as fertilizers, combustibles or inert aggregate material

Huge reduction of inconveniences to the neighborhood due to transport noise and dust

Economical and ecological replacement option to landfills

Net GHG reduction when producing fertilizing biosolids

Superior results

“The La Pinière wastewater treatment plant in Laval, dewaters and dries, on an average day, around 30 metric tons of municipal sludge (dry basis) from an average solids content of about 28% at the drying system inlet to a solids content of more than 92% at the outlet. The biosolids produced in this process are certified as BNQ* Grade in the Province of Quebec. A part of these biosolids is distributed as fertilizers and a larger part is currently used as an efficient combustible and process addition in a cement plant in the region. This drying system was rated by Berlie Technologies Inc. for a nominal evaporative capacity of 5 metric tons per hour and processes sludge for an estimated population of 280,000 people.” – Citation from the management

* BNQ Grade is an equivalent, in the Province of Quebec, to the United States EPA-503 Process to Further Reduce Pathogens grade known as Class A Biosolids

Closed Loop Rotaty Dryer - Superior Results

CLOSED LOOP ROTARY DRYER

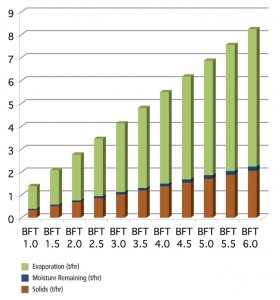

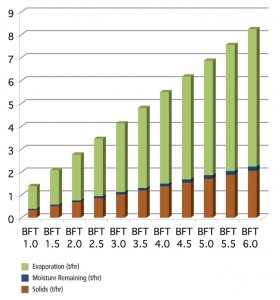

Series 1.0, 2.0, 3.0, 4.0, 5.0 & 6.0

Worldwide references

Berlie Technologies Inc. contracted and delivered, as turnkey projects, 11 biosolids drying and pelletizing plants in North America, Europe and Middle East.

There are 48 references of plants operating with this technology around the world.

Advanced technology

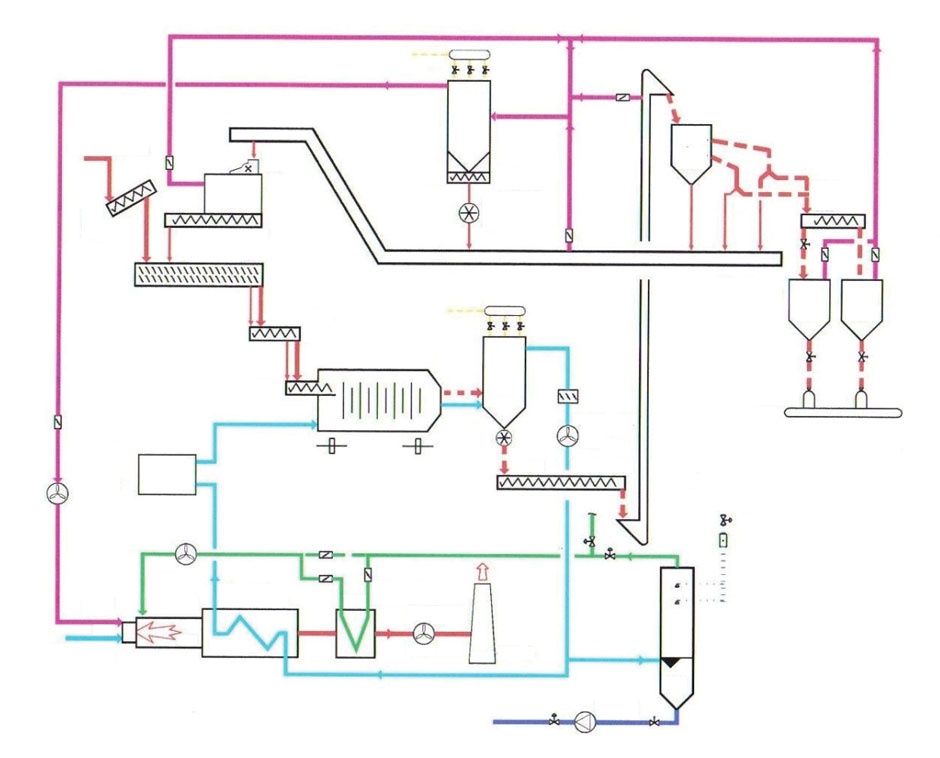

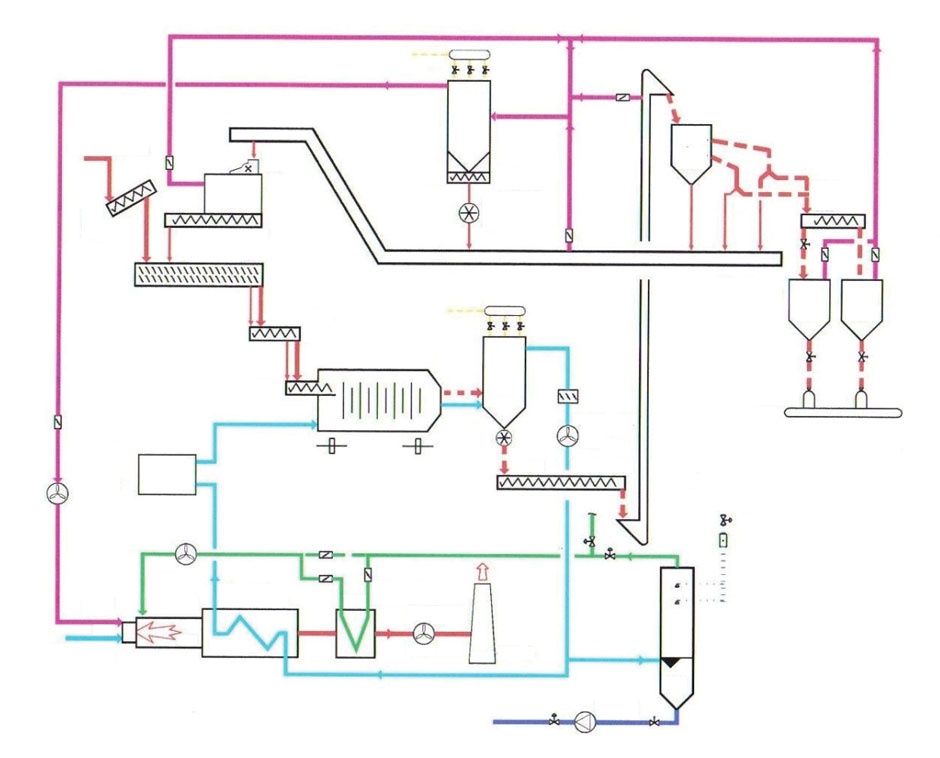

In our Patented Closed-Loop Design, oxygen is replaced by recycled steam in the dryer drum, which eliminates process risks and improves drying efficiency.

System configuration

Performance chart

Energy savings and recovery

When processing dewatered primary sludge, this drying system can be operated without the purchase of fossil fuels if its end product is recycled on site as an efficient heat source.

When processing dewatered digested sludge from anaerobic digestion, this drying system can be operated without the purchase of fossil fuels if the digestion biogas is recycled as an efficient heat source.