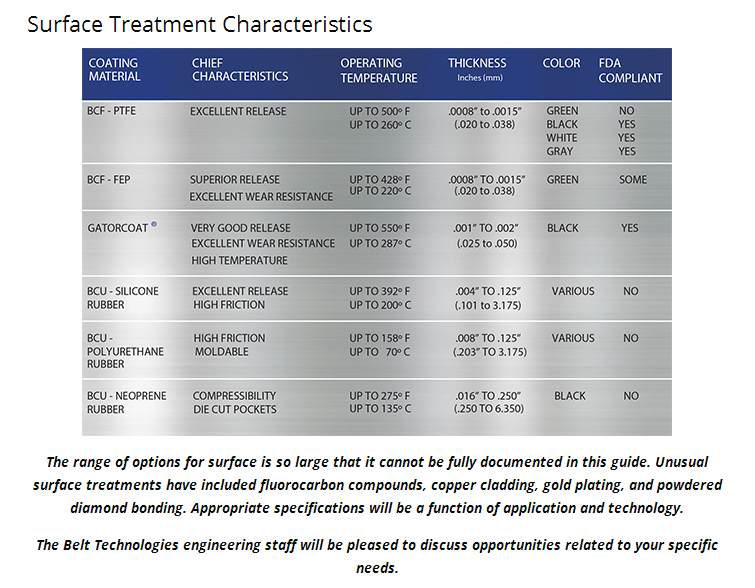

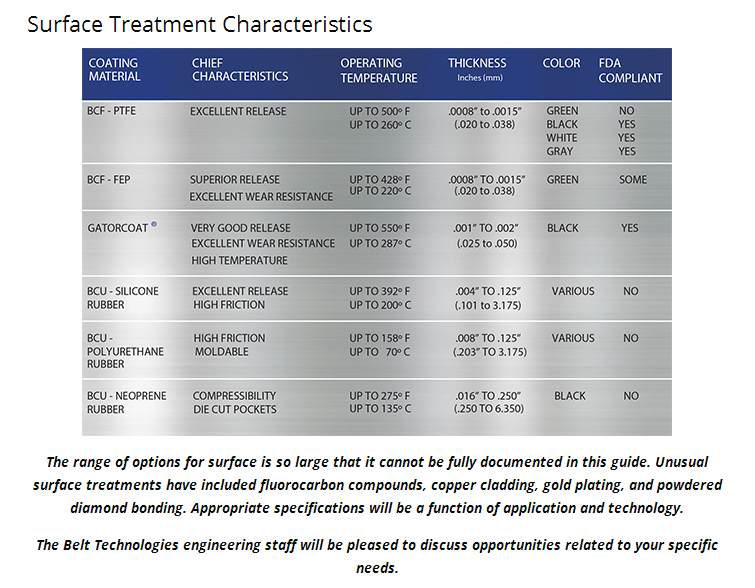

Surface treatments give engineers the opportunity to alter the natural surface properties of a metal belt, tape, or pulley. Surface treatments may be applied to one or both surfaces of a belt, tape, or to a pulley. Application methods include coating, plating laminating, and bonding.

Depending on the method selected, the thickness of a surface may be as little as .0005”. The surface can be uniform or, to provide pockets on the belt surface for transporting small components, punched or die cut. Vacuum holes can be combined with pockets for more positive orientation and retention of delicate parts during the transportation process.

Surface Treatment Options

SILICONE:

When the environment is not suitable for other coatings, silicone may be a good option. Silicone has unique properties including a high friction surface, release properties, the ability to withstand elevated temperatures, and extreme flexibility. Bonding silicone to metal belts can be difficult, but workable solutions do exist.

GATORCOAT®:

FDA compliant GATORCOAT® coatings are high release and extremely wear resistant. Its unique three-coat system of internally reinforced metallic material have a high cure, nonstick surface is over ten times more abrasion-resistant than Teflon. It is household chemical resistant and features high nonstick properties, stain resistance and performance at high temperatures. It is different from all other nonstick coatings in that the basecoat contains a carefully chosen and blended combination of resins.

TEFLON®:

Teflon became a household word as a nonstick coating for cookware. Teflon is actually available in a variety of formulations, each having distinct operating properties regarding release characteristic, lubricity, resistance to abrasion, temperature range, and color.

ECLIPSE®: FDA-compliant Eclipse coatings are high-release and extremely wear-resistant coatings. Its unique, three-coat, high-cure, internally reinforced, nonstick surface is over ten times more abrasion-resistant than Teflon. It is resistant to household chemicals and features high nonstick properties and stain resistance and can perform at high temperatures. It is different from all other nonstick coatings in that the basecoat contains a carefully chosen and blended combination of resins.

The midcoat (actually a basecoat used in other reinforced systems) also contains the special reinforcing element, while the topcoat is rich in fluoropolymers and is dedicated entirely to nonstick release properties.

HARD COAT ANODIZE:

Hard coat anodization is an electrochemical process used to increase the hardness, wear characteristics, and corrosion resistance properties of aluminum pulleys. The process forms an integral part of the metal, both penetrating and building up on all pulley surfaces. The coating thickness is uniform and mirrors the precision of the pulley itself.

URETHANE OR NEOPRENE:

Both urethane and open or closed cell neoprene change the surface coefficient of friction of a metal belt and also can act as a nest for delicate parts. These materials are securely bonded to a metal belt. Prior to bonding, they can be die cut when a specific pocket geometry is important.