Spray Coolers

Spray Coolers

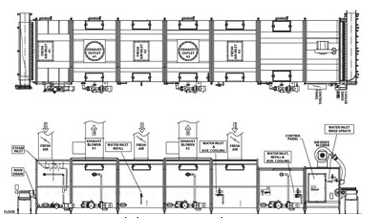

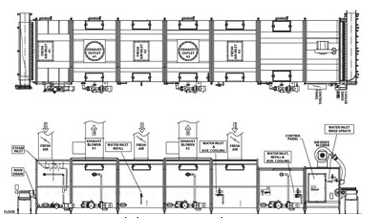

The Busse/SJI Spray Cooler is designed to meet the most exacting hot-filled container processing requirements. Busse/SJI Spray Cooler technology has been developed over years of extensive research and successful installations.

The modular, robust, stainless steel construction combines first class workmanship including safety and reliability. Available cooling methods include closed loop tower systems, closed loop chilled water systems, high water flow systems as well as a combination of the cooling methods to maximize the cooling efficiency and minimize operating cost. Available options include hot hold pasteurizing zones, tempering zones, infeed and discharge conveyors and clean in-place systems. Other options are available that enable Busse/SJI to customize each cooler to specific application requirements.

Mastering the science of product cooling, Busse/SJI serves the ever-changing food and beverage industry with the most innovative coolers to be a world leader in coolers and product handling systems.

Meeting the exact requirements of rigid or flexible container processing, we deliver reliable performance together with responsible water conservation methods.

Key Standard Features

All stainless steel T304 construction.

Precise automated seam welding.

Stainless drive and idle steel shafts.

Babbitted center bearings for durability and long life.

Heavy duty polypropylene transport chain.

Stainless steel piping systems.

Sloped sump bottoms for easier cleaning.

High volume, low pressure close coupled spray pumps.

High flow basket suction strainers.Isolation valves for quick change pump maintenance.

Large orifice spray nozzles to eliminate nozzle plugging.

Wide angle full cone spray pattern for reduced nozzle count.

Flow-Through transport bed for maximum heat transfer.

Large access doors for easy cleanout.

Thermometers and pressure gauges at all pump headers.Heavy duty shaft mounted main drive.

Inside belt returns for drip free plant floors.

NEMA 4X control panel with micro PLC and AC inverter for main cooler drive.

Air knife water blow off system.

Pre-wiring of cooler with rigid galvanized conduit.

Available Options

Internal evaporative cooling package for maximum water savings.

Glass tempering zones with direct steam injection water heating systems.

Hot water pasteurizing systems with precision temperature control.

Closed loop external evaporative cooling tower heat exchanger systems.

Observation windows and marine lighting.

Rotary spray Clean-In-Place or Boil-Out systems.

Double screened drop boxes and pressure strainers.Advanced PLC controls with graphical user interface.

Custom designed and precision fit arrowhead infeed and discharge conveyor systems.

Dynamic transfers and small pitch transport chain to eliminate deadplate transfers.

Short stroke continuous motion push-arm for non-round container loading.

Automatic water temperature control/dew point monitoring systems.

Discharge line switch shutdown system