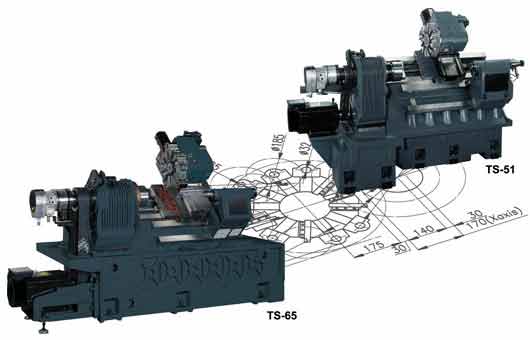

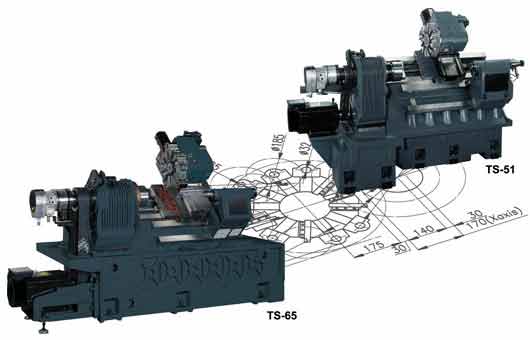

Machine & technology

The new slant bed CNC TEACH-IN lathe from ARIX

gives extraordinary machining capacity, stability and precision.

The specially designed structure enhances the heavy cutting capabilities

and easy operation TEACH-IN controller makes the quick and simple setup

and programming.

Heavy duty Meehanite Cast Bed

The optimal structure is ribbed for maximum stiffness.

The gray cast iron offers excellent damping properties and Meehanite process ensures the casting is properly heat treated and annealed before aging.

The homogenized casting is free from any stress concentrations that can withstand any heavy-duty cutting.

45°slant bed construction assures solid support of turret and efficient chip removal.

Hand Scrapped Box side ways

The Cast-in slide-ways generates the maximum rigidity.

The heat treatment by high frequency induction heating produces a depth of 0.5 mm maximum wear resistance structure with tough internal core.

The precise & fine hand scrapping on all contact surfaces ensure the accuracies are held throughout machine life.

High rigidity, High Precision Spindle

The spindle is encased in the ribbed headstock for maximum heat dissipation.

The thick cast iron case can damp all the vibration from cutting.

For spindle configuration, the angular thrust bearings to absorb axial cutting forces and the roller bearings with large bearing areas facilitate heavy cutting capacity.

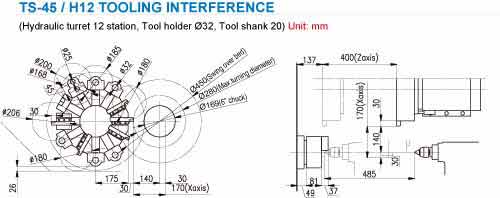

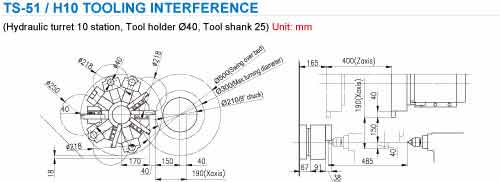

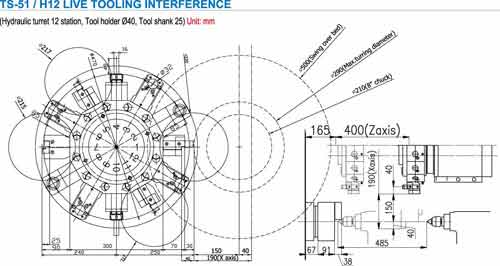

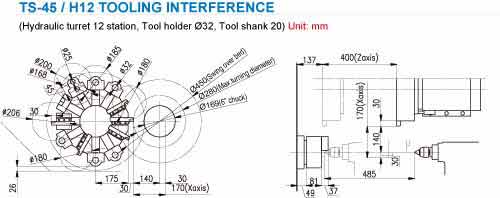

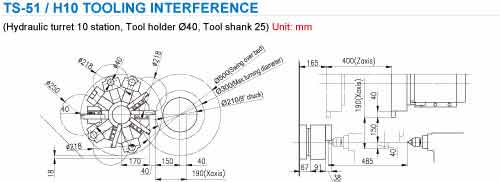

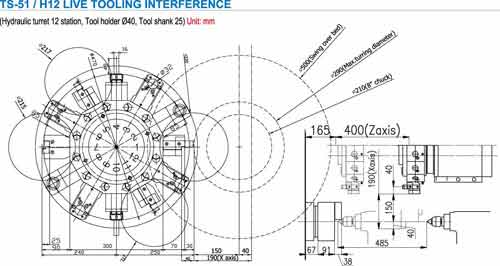

Fast indexing, durable turret

The turret has Curvic coupling for high positioning accuracy and the hydraulic clamping for heavy cutting.

The fast indexing with bi-directional random selection can shorten the setup time.

The hydraulic index motor offers optimum service life.

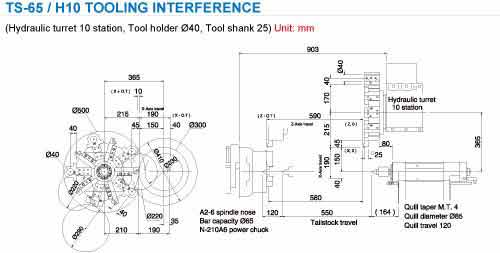

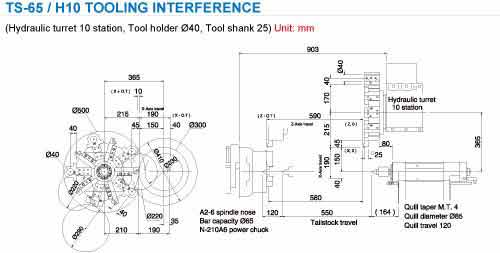

Programmable tailstock

The tailstock on slide way gives maximum clamping stability.

The smooth tow along action is done by turret.

The hydraulic clamping to bed has variable hydraulic pressure to tailstock quill.

All tailstock movements are programmable bye M-code.

Direct Drive Mechanism

High precision preloaded ballscrews for reduced backlash.

Direct coupling eliminates motor backlash and improves torque transmission characteristics.

Absence of belt or gear drives removes transmission vibration.

Technology & Options

Controls

Specifications

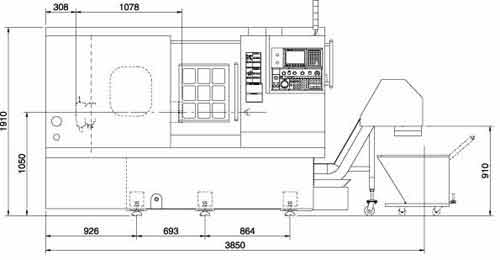

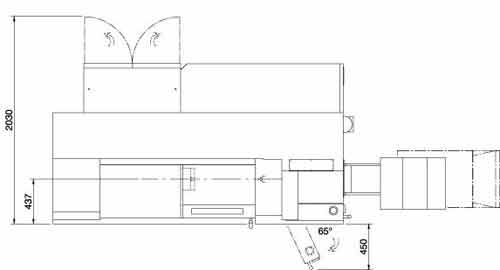

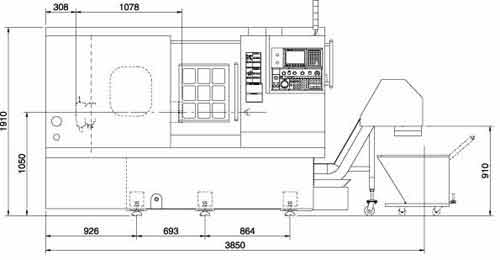

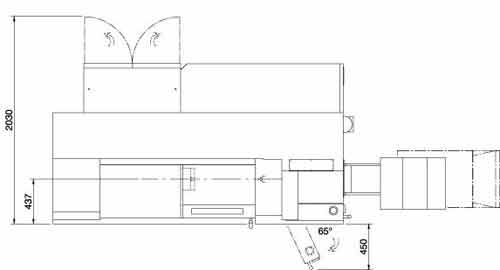

Floor Plans