Reduce your sample analysis costs by 66%

The High Throughput Viscometer HTV is an all-in-one automation and robotic system for viscosity measurements of up to 2000 samples a day.

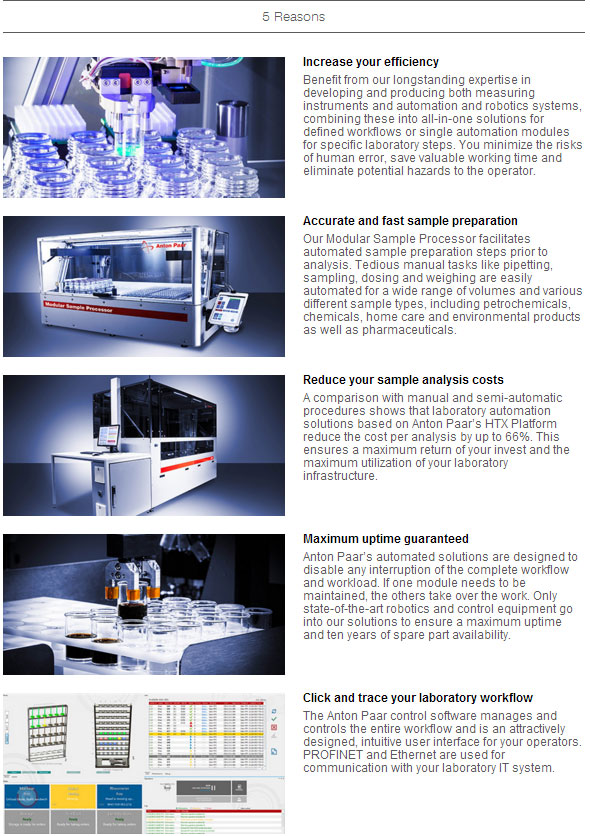

The HTV links Anton Paar’s Stabinger ViscometerTM SVM 3000 with an automation and robotics platform. The flexibility of the HTV enables you to adapt the system to your current and future throughput requirements, from one module up to 10 modules.

The smart modular concept of the HTV enables Anton Paar to offer customized solutions to almost all industry segments.

The HTV standard configuration is intended for used oil samples and measures any other viscous sample.

Key Features

Viscosity-independent

Anton Paar’s Stabinger ViscometerTM SVM 3000 is a rotational viscometer. No capillaries need to be changed and it coversa broad range for kinematic viscosity determination.

Measurement of viscosity and density in one

The unique Anton Paar Stabinger ViscometerTM SVM 3000 is able to measure the dynamic viscosity and density in one cycle and calculate the kinematic viscosity and the viscosity index at the used measurement temperature.

The HTV standard configuration provides measurements at 40 °C and 100 °C. Any other temperature can be optionally defined.

Verification

The all-in-one concept includes the Anton Paar Control Software which manages the complete workflow and controls programmable verification cycles with up to 2 reference standard solutions to ensure correctness of the received results.

Compliant

Anton Paar’s Stabinger ViscometerTM SVM 3000 is the only instrument to combine the required precision for ASTM D7042, which is equivalent to ASTM D445/ISO 12185, and measurement of the viscosity index according to ASTM D2270/ISO 2909.

Economic and efficient cleaning and sample handling

Well-thought-out workflows prevent contamination through optimized cleaning routines and an intelligently engineered filling and cleaning module. Solvent consumption and therefore running costs are minimized.

Measured samples are automatically collected in the implemented waste container. The sample vials can either be disposed of via the integrated trash chute or placed back into the initial tray.

Modular

To provide the utmost flexibility the HTV comes in a modular design. Each module works independently.

The system is extendable from one to 10 modules and offers a flexible space structure for measurement devices and/or storage places.

This results in a high throughput of up to 2000 samples per day and up to 24/7 operation. This enables you to react to your current and future throughput.

Smart module configuration

The smart module configuration allows the independent use of each module. The sample workflow never stops. When one module needs periodic maintenance the others take on the additional work. This is managed by the Anton Paar Control Software.

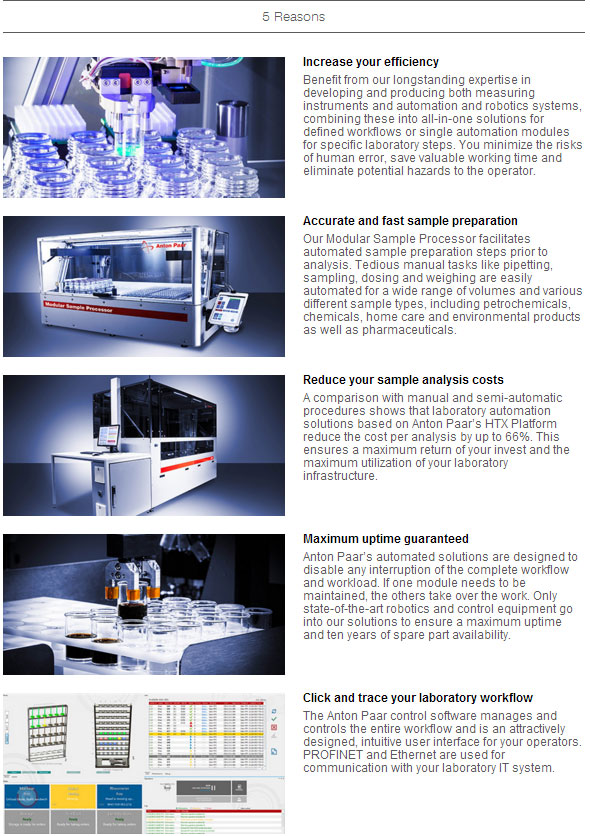

Anton Paar Control Software

The Anton Paar Control Software uses established industry standard control systems (Siemens SIMATIC and FESTO CPX) and provides maximum time efficiency by sample prioritization. Information on system errors via SMS is optionally offered.

Each sample and measurement step is logged with a time stamp and therefore fully traceable. User traceability is given by the implemented user management.

Communication

PROFINET and Ethernet are used for communication.

Data transfer is via LIMS as CSV files or SQL database.

The machine and customer network are separated to contribute to the user’s safety requirements.