Laboratory Mixers

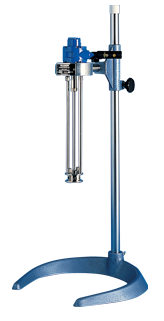

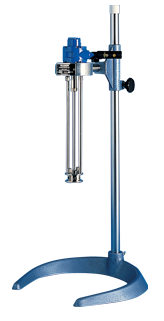

The latest development in high shear lab mixing – the new Silverson L5M-A – is ideal for all laboratory work, research and development, QA analysis and small scale production in all industries.

The L5M-A Laboratory Mixer is suitable for the widest range of applications – mixing, emulsifying, homogenizing, disintegrating and dissolving – with an efficiency and flexibility unmatched by other machines. With a capacity from 1ml up to 12 liters and the ability to mix in-line with flow rates up to 20 liters/minute, they offer excellent reproducibility when scaling up to full-scale production and provide an accurate and easy means of forecasting the performance of larger Silverson machines under full-scale working conditions.

The multifunctional L5M-A lab mixer features touch screen control with digital tachometer, programmable integral timer and amperage display. This level of instrumentation is invaluable for applications where process validation and reproducibility are required.

L5M-A Laboratory Mixer

Over 40 interchangeable mixing assemblies are available for L5 Series Laboratory mixers. The unit is finished in a tough, easy to clean, non-chip white nylon coating. All wetted parts are in 316L stainless steel with the exception of the bush which may be bronze alloy or PTFE. The mixing unit may be effortlessly raised and lowered using the touch pad control, which offers increased cleanliness and reliability.

L2/Air (Compressed air)

Designed for use in explosion proof areas, the L2/AIR is powered by an intrinsically safe air motor and will accept any L5 series mixing assembly. Capacity is from 1ml up to 12 liters.

AX Pilot Scale

The AX series of mixers is a small scale production unit widely used in industry, pilot scale plants and research institutes, etc. These mixer models have a capacity of up to 50 liters.

Sealed Unit Lab Mixer

The Sealed Unit Laboratory Mixer is designed for working on sterile materials where it is essential to exclude airborne contamination. Capacity is from 1ml up to 5 liters. Special assemblies are available for working under vacuum.

Laboratory Mixers - How It Works

The advantages of Silverson's high shear rotor/stator laboratory mixer over simple conventional stirrers or agitators stem from the multistage mixing/shearing action as materials are drawn through the specially designed Silverson workhead - the heart of every machine.

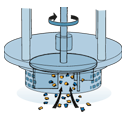

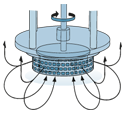

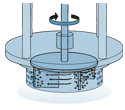

Stage 1

The high-speed rotation of the rotor blades within the precision-machined mixing workhead exerts a powerful suction, drawing liquid and solid materials upwards from the bottom of the vessel and into the center of the workhead.

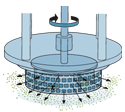

Stage 2

Centrifugal force then drives materials towards the periphery of the workhead where they are subjected to a milling action in the precision-machined clearance between the ends of the rotor blades and the inner wall of the stator.

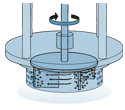

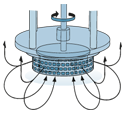

Stage 3

This is followed by intense hydraulic shear as the materials are forced, at high velocity, out through the perforations in the stator and circulated into the main body of the mix.

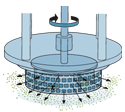

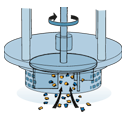

Stage 4

The materials expelled from the head are projected radially at high speed towards the sides of the mixing vessel. At the same time, fresh material is continually drawn into the workhead maintaining the mixing cycle. The effect of the horizontal (radial) expulsion and suction into the head is to set up a circulation pattern that minimizes aeration caused by the disturbance of the liquid's surface.

Laboratory Mixers - Workheads

A comprehensive range of workheads and screens is available for all Silverson high shear mixers. These easily interchangeable workheads offer great versatility by allowing any machine to be adapted to perform a wide range of mixing operations including emulsifying, homogenizing, disintegrating, dissolving, dispersing, blending, particle size reduction and de-agglomerating. Changing from one head or screen to another is quick and simple.

General Purpose Disintegrating Head

This is the most versatile of all the heads, giving an exceptionally vigorous mixing action. Ideal for general mixing applications. It uses also include the disintegration of solids and the preparation of gels and thickeners, suspensions, solutions and slurries.

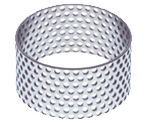

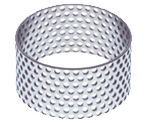

Square Hole High Shear Screen™

The configuration and fine internal tolerances of this stator provide exceptionally high shear rates, ideal for the rapid size reduction of soluble and insoluble granular solids. It is also suitable for the preparation of emulsions and fine colloidal suspensions.

Emulsor Screens

Suitable for liquid/liquid preparations and especially useful for all emulsions. Available in fine and medium (standard) perforations.

Axial Flow Head

This head expels material vertically upwards instead of horizontally and is used in certain circumstances where aeration needs to be minimized, and to maintain heavy insoluble solids in suspension.

Slotted Disintegrating Head

For the disintegration of fibrous materials such as animal and vegetable tissue, as well as the disintegration and solubilization of “elastic” materials such as rubbers and polymers. Vertical and diagonal slotted heads are available.

Pump Head

This converts the mixer into a non-positive pump which with the use of a flexible hose and valve can be used to fill individual containers.

Tubular Mixing Units

A series of interchangeable Tubular mixing units is available for Silverson Laboratory mixers, suitable for use in narrow-necked containers:

1” Tubular - Supplied with interchangeable screw-on, General Purpose Disintegrating Head and Square Hole High Shear Screen™ or Integral, Open-ended, Vertical Slotted Disintegrating Head. Interchangeable, screw-on Slotted Disintegrating Heads are available as extras. Capacity, depending on viscosity, 50 ml up to 500 ml.

3/4” Tubular – Generally as 1” Tubular. Capacity 20ml up to 250ml.

5/8” Micro – Solid one-piece construction. Capacity 5ml up to 50ml.

3/8” Mini-Micro – Generally as 5/8” Micro. Capacity 1ml to 10ml.

Laboratory Mixers - Technical Information

Model L5M-A

Capacity

1ml up to 12 liters.

Motor Unit

Robust two-piece designed for cool, quiet and continuous operation.

Motor

1hp (750W) 110 volt, single phase (220 volt optional), 60 Hz. Nominal maximum speed 8000 rpm (6000 rpm under full load).

Speed Control

Infinitely variable electronic speed control with integral on/off switch.

Electric Rise & Fall Bench Stand

The mixing unit may be effortlessly raised and lowered using the push-button control on the motor unit.

Construction

All wetted parts are in grade 316 stainless steel with the exception of the bush, which may be bronze alloy or PTFE.

L5 Series mixers are finished in a tough, easy-to-clean, non-chip white nylon coating. The flat base is covered by a removable non-slip mat, which is resistant to most solvents.

Assemblies

Over 40 interchangeable mixing assemblies are available including In-Line, Ultramix, Duplex and Tubular assemblies.